The Miner Operated Survey System (MOSS) is a underground operations software that allows miners to advance the face independently. MOSS provides miners, engineers, and geologists with real-time information regarding compliance to design.

Mining operations demand strict adherence to mine plans to maximize efficiency and minimize costs. As mining progresses, challenges such as overbreak, underbreak, and deviation from design pose significant financial and productivity risks. Overbreak, as well as damaged zone, significantly impact project costs, construction period, safety, and performance of the underground structures. |

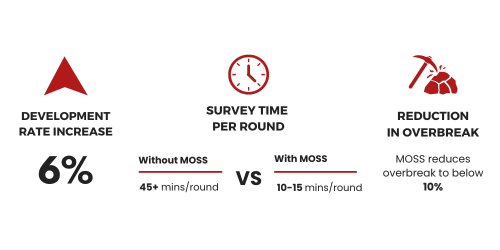

MOSS allows for operations, engineering, and geology to remain updated in real-time on all active headings' progress. It allows for immediate response to any discrepancies at the face, drastically reducing the potential for costly and time-consuming rework. The system has been proven to reduce overbreak to below 10%, promoting best practices among miners. MOSS provides miners with all required information, allowing for refinement in drilling techniques, maintaining consistency, and adhering closely to design specifications. This immediate feedback system not only enhances the quality of work but fosters greater accountability among miners. |

Using MOSS to collect the necessary data is a one-person job, thereby reducing workforce cost while increasing safety by having fewer people in the development heading.

The MOSS software supports a wide range of Leica robotic total stations, including the state-of-the-art MS60 Multi Station. MOSS allows a miner to advance the face independently, eliminating survey down time entirely.

Surveyors can be leveraged for more critical tasks and allocated to different areas throughout the mine.

With every MOSS mark-up completed by the miner, the previous rounds face profile (overbreak, underbreak), tope, and elevation is recorded and saved to the miner's tablet.

The entire seven-step process takes on average 10-15 minutes.

With the miners tablet displaying up-to-date driving layouts, miners are able to compare actual development to planning.

MOSS generates an adjusted drill-hole pattern based on the face profile. This optimal pattern is derived using a projection of the next round.

MOSS has proven direct cost savings due to the real-time data provided to the miner at the face. Each time the MOSS process is completed, the mine plans are updated, this results in newly updated plans every day.

Once the miners tablet is synced, data is shared via the network and available to anyone with connectivity.

Data collected with every MOSS mark-up includes:

• Face Profiles (overbreak & underbreak)

• Topes (drift outline)

• Elevation (height of back and floor, grade change)

Real-time surveying performed by the drill crew which eliminates the need to wait for the surveyor. Improves cycle times and increases productivity. |

When a mine uses MOSS it drastically reduces overbreak to 10% and takes the guessing out of the process. |

Lower operational costs by:

|

Today’s modern mining industry is safer, more efficient, and more cost-effective, due to innovation and the adoption of new technologies. MOSS checks off all these categories. MOSS speeds up cycle time by providing the ability for one miner to perform tasks previously completed only by the survey crew in 10-20 minutes that would have previously taken up to one hour. In addition, MOSS eliminates the serious hazard of workers being exposed to open cavities with its cavity monitor survey feature.